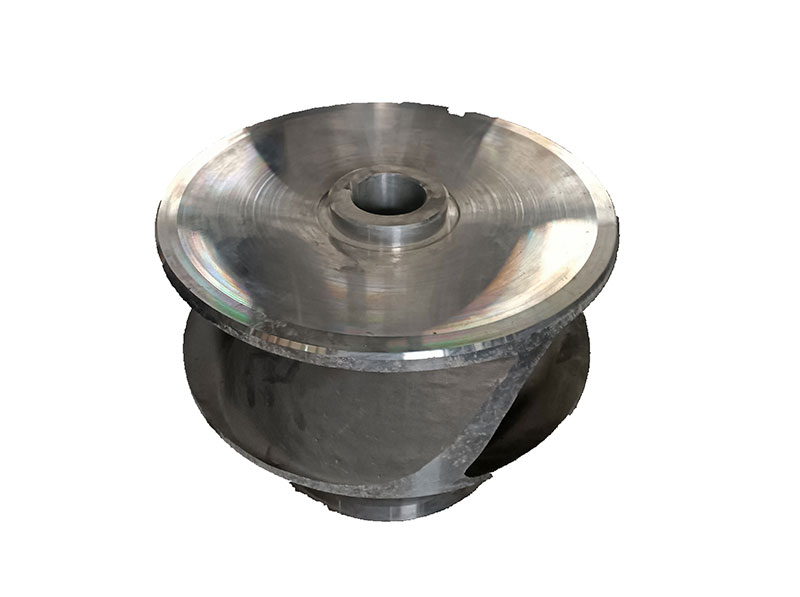

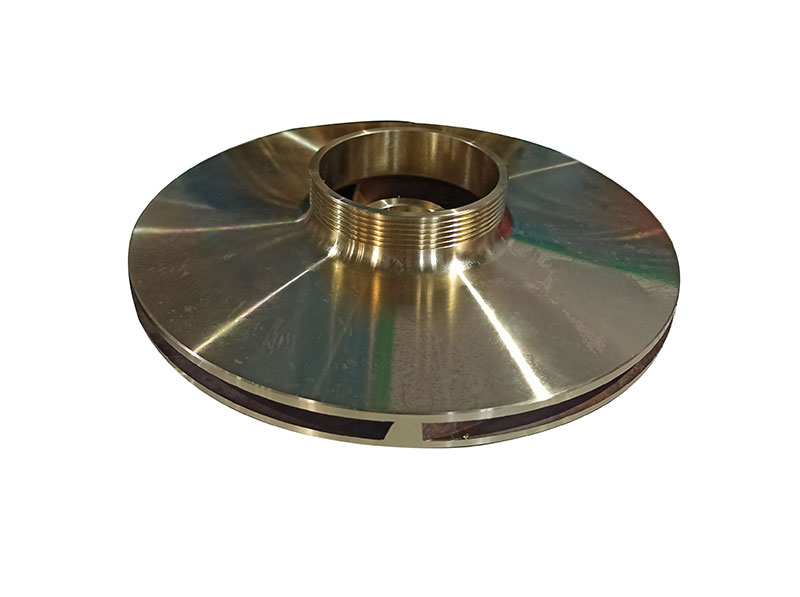

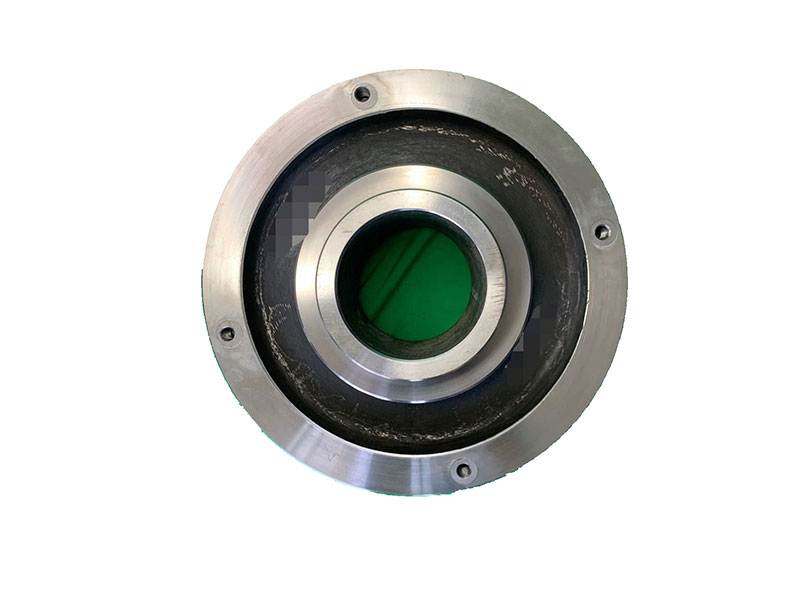

The quality of castings for volute pumps has a great influence on the performance of mechanical products. For example, the wear resistance and dimensional stability of machine tool castings directly affect the accuracy and maintenance life of the machine tool; the size, accuracy and surface roughness of the impeller, housing and hydraulic parts of various pumps directly affect the pump And the working efficiency of the hydraulic system, energy consumption and cavitation development, etc.; the strength and shock resistance of the internal combustion engine cylinder block, cylinder head, cylinder liner, piston ring, exhaust pipe and other castings directly affect the working life of the engine.

In the realm of industrial engineering, precision and reliability are the cornerstones of success. Every component in a machinery system plays a pivotal role in ensuring its seamless operation. One such component that exemplifies engineering excellence and durability is the Volute Pump Castings. In this comprehensive guide, we will delve into the remarkable characteristics, manufacturing processes, and applications of Volute Pump Castings, with a specific focus on our company's commitment to delivering top-tier solutions.

English

English

![]()

English

English

Russian

Russian

French

French

Spanish

Spanish