Valve Stainless Steel Parts

English

English

![]()

English

English

Russian

Russian

French

French

Spanish

Spanish

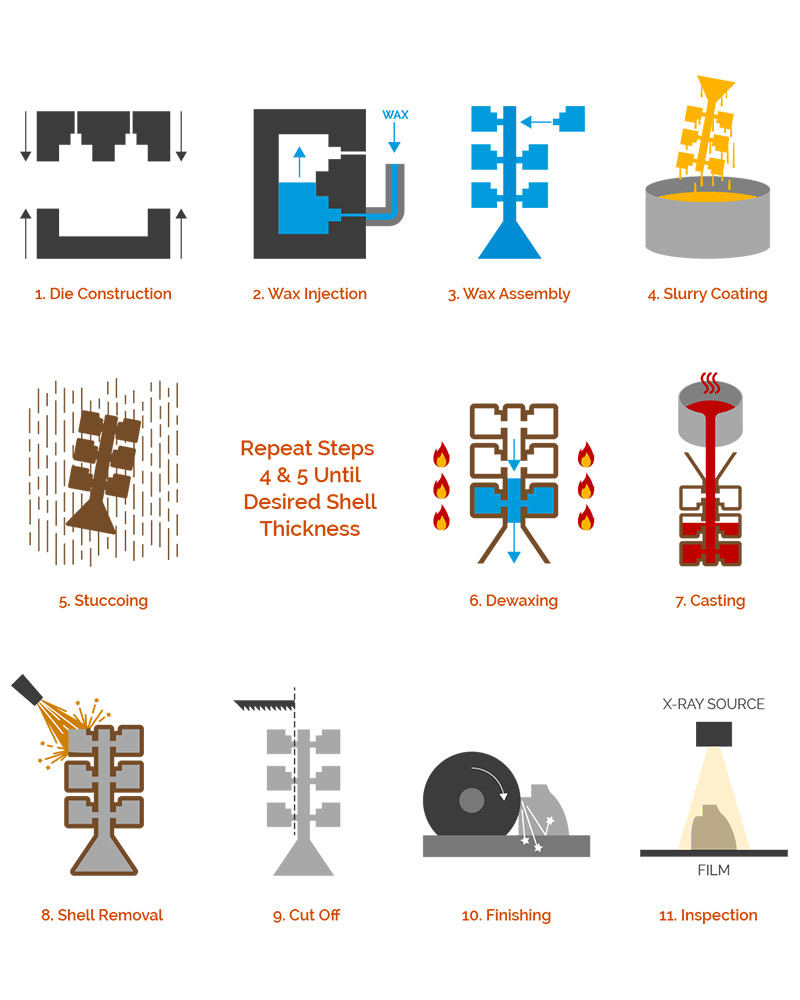

An investment casting is a manufacturing process where a wax pattern is used to form a ceramic mold. This mold is then used to cast metal parts. The investment casting process has been used for centuries to produce high-quality, complex metal parts.

The process begins with the creation of a wax pattern. This wax pattern is an exact replica of the desired final product. Once the wax pattern is complete, it is placed in a mold. The mold is then filled with a liquid ceramic material.Once the ceramic material hardens, the mold is heated until the wax melts and runs out. This leaves a negative impression of the desired final product in the ceramic mold.The molten metal is then poured into the mold and allowed to cool. Once cooled, the ceramic mold is broken away, revealing the completed investment casting.

The history of investment casting is long and varied, with the earliest known examples dating back to ancient times. The process has been used to create everything from small objects like jewelry to large objects like statues.In more recent history, the industrial revolution saw the development of new materials and methods that made investment casting more reliable and efficient. This led to its widespread use in a variety of industries, including automotive and aerospace.Today, investment casting is an essential manufacturing process for many industries. It’s used to create parts with complex shapes that would be difficult or impossible to produce using other methods. And thanks to advances in technology, the process is only getting more precise and efficient.

In the early days of investment casting, the process was known as “lost wax” casting. This was because the original mold was made from beeswax. The wax model was then coated with a refractory material. Once the coating hardened, the wax was melted out, leaving a hollow cavity in the shape of the final product. molten metal was then poured into the cavity and allowed to cool.

The modern investment casting process is essentially the same, but there have been some refinements over the years. For instance, more advanced materials are now used for both the mold and the final product. And, computer-aided design (CAD) and manufacturing (CAM) technologies have made it possible to create more complex shapes than ever before.

The history of investment casting can be traced back to the ancient world, where the lost-wax process was used to create small sculptures and jewelry. The technique was further developed in medieval Europe, and by the 19th century, it had become an important industrial process for making precision parts.

Today, investment casting is used to produce a wide variety of metal parts, from small components to large turbine blades. The process is particularly well suited for parts with complex shapes or intricate details that would be difficult or impossible to produce using other methods.

Investment casting is a process that has been used for centuries to create metal parts with intricate designs. The process begins with a mold being created from a wax model. The mold is then placed in a kiln where the wax melts, leaving a negative impression of the original model. molten metal is then poured into the mold and allowed to cool. Once cooled, the mold is broken away to reveal the final product.

There are many benefits to using investment casting over other methods of metal fabrication, such as die casting or machining. Investment castings can be made with very tight tolerances, making them perfect for parts that need to fit together perfectly. The process also allows for very intricate designs that would be impossible to create with other methods.

Investment casting, also known as lost-wax casting, is a process in which a mold is created from a wax replica of the desired object. The mold is then filled with liquid metal, and the wax replica is melted and drained away. This leaves a hollow cavity in the shape of the final object.

The benefits of investment casting include its ability to produce objects with very intricate details, as well as a smooth surface finish. Additionally, investment casting can be used to create objects from a variety of metals, including steel, aluminum, and bronze.

Investment casting is a process where a mold is created from a wax model. The mold is then filled with a metal, such as brass or bronze. The metal is then cooled and the wax is melted away, leaving the metal piece.

1. Investment casting, also called lost-wax casting, is one of the oldest and most versatile manufacturing processes.

2. It can be used to produce parts with intricate geometries that would be difficult or impossible to machine using traditional methods.

3. The process begins with a wax model of the desired part. This model is then coated with a refractory material, typically a ceramic slurry.

4. Once the coating has hardened, the wax is melted out, leaving a void in the shape of the desired part.

5. Molten metal is then poured into the void, and allowed to cool and solidify.

6. The final step is to remove the casting from the mold material, which can be reused for future castings

The process of investment casting is an ancient art that has been used for centuries to create metal objects from a variety of materials. The process begins with the creation of a mold, which is then filled with a liquid metal. Once the metal has cooled and solidified, the mold is broken away to reveal the finished product.

We provide our customers with a full range of products, services and solutions to help them remain competitive in their respective fields. We handle every job with the best process for lowest cost, best quality and highest efficiency. Our capabilities are comprehensive and include engineering design, sample development, process control, heat treatment, machining, inspection, and shipping and delivery. Thanks to our extensive experience and expertise in casting and machining, we are able to produce a wide range of parts and assemblies serving a wide range of industries and applications.

We attach great importance to quality. We are ISO9001/2015, AS9100 ISO45001:2018 and PED 97/23/E, ADW0 and API 6D certified by BV, TUV and DNV. The implementation of the ISO9001 quality management system ensures the good performance of our products and services, enabling us to establish long-term business relationships with customers all over the world.

The field is required.

The field is required.

The field is required.

The field is required.

Send